Shrink Wrap: From Radiation Labs to Everyday Life

Heat shrink wrap, that magical plastic that conforms perfectly to almost anything, has a surprisingly interesting history rooted in post-WWII innovation. Here's a journey through its evolution:

1. The Spark of Discovery (1950s)

Radiation's Unexpected Effect: Scientists experimenting with the effects of radiation on materials (think early nuclear research) noticed something peculiar: certain plastics, when irradiated, gained a "memory." They could be stretched, but when heated, they'd shrink back to their original form.

Paul Cook, the Pioneer: A chemical engineer named Paul Cook, working at Stanford University, is often credited with pioneering the development of heat shrinkable materials. He founded Raychem Corporation, which focused on radiation chemistry and produced the first commercial heat shrink tubing for electrical insulation.

2. Early Applications (1960s)

Wiring and Insulation: Initially, heat shrink tubing was primarily used to insulate electrical wires and components, providing a protective and secure covering.

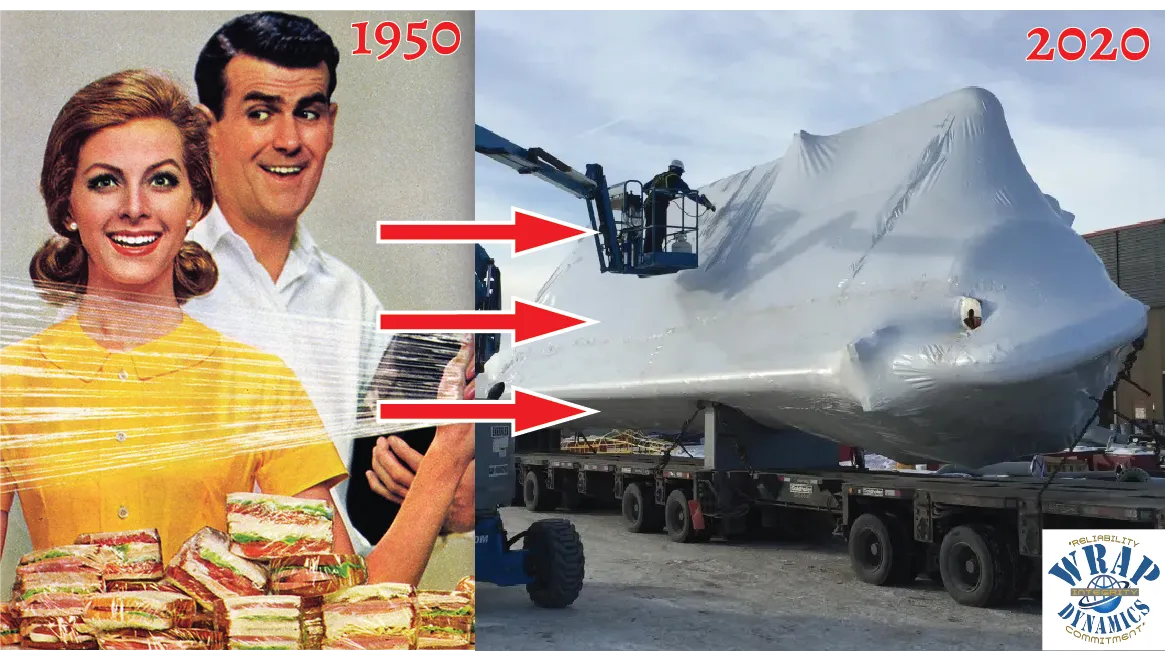

Packaging: The packaging industry quickly saw the potential. Early shrink wrap was used for bundling products, offering a tamper-evident seal and a more streamlined look than traditional packaging.

3. Evolution and Expansion (1970s - Present)

Material Advancements: Scientists developed new polymers and formulations, leading to a wider variety of shrink wrap materials with different properties:

Polyolefin: Became the most common material for its versatility, strength, and affordability.

PVC: Used for its clarity and resistance to chemicals.

Polyvinylidene Chloride (PVDC): Offered superior barrier properties for food packaging.

Application Explosion: Shrink wrap found its way into countless industries:

Construction: Protecting buildings, scaffolding, and materials.

Marine: Winterizing boats and preserving vessels.

Agriculture: Wrapping hay bales and protecting crops.

Art & Preservation: Safeguarding delicate artifacts and museum pieces.

And many more!

4. Modern-Day Shrink Wrap

Sophisticated Technology: Today's shrink wrap comes in a wide range of thicknesses, colors, and specialized properties (UV resistance, flame retardancy, anti-corrosion).

Customization: Companies like Wrap Dynamics offer custom shrink wrap solutions tailored to specific needs, including printing, ventilation, and unique applications.

Sustainability: With growing environmental awareness, biodegradable and recyclable shrink wrap options are becoming increasingly common.

From its humble beginnings in a radiation lab to its widespread use across industries, heat shrink wrap has evolved into an essential tool for protection, preservation, and efficiency. As technology continues to advance, we can expect even more innovative applications and sustainable solutions in the future.

Let Wrap Dynamics take care of your Wrapping needs.

“WE KNOW WRAP"

Call us, we got you covered!

Ph# 587-316-2805

Email: [email protected]

Web: www.wrap-dynamics.com